ELECTRONIC THROTTLE SYSTEMS

E-GAS COMPACT – “FLY BY WIRE”

VDO Europe developed electronic throttle systems in 1978 to accommodate articulated buses and their throttle systems. Since that time the system has been further developed into a cost effective replacement for throttle and Bowden cable based accelerator systems. Enhancements include road speed limiting functions, cruise control, rev limit and fixed RPM functions suitable for PTO and stationary engines.

In Victoria due to occupational health and safety concerns we have adapted the system to suit most brands of fork lift vehicles. The VDO E-gas compact system has proven its reliability and longevity in this demanding market segment providing a tamper proof means of limiting vehicle speed without affecting total lift capacity or engine performance.

The design flexibility of the E-Gas compact system means that it can perform in environments as diverse as

- Generator speed control – state emergency service lighting trucks

- Engine speed governor – concrete pumps, remote engine control

- Match RPM of two engines – bulldozer applications

- Forklift speed control – warehouse applications

- PTO system control – drain cleaning machines

- Bus electronic throttle – bus fleets

- Pump speed control – fire engines

SYSTEM OVERVIEW:

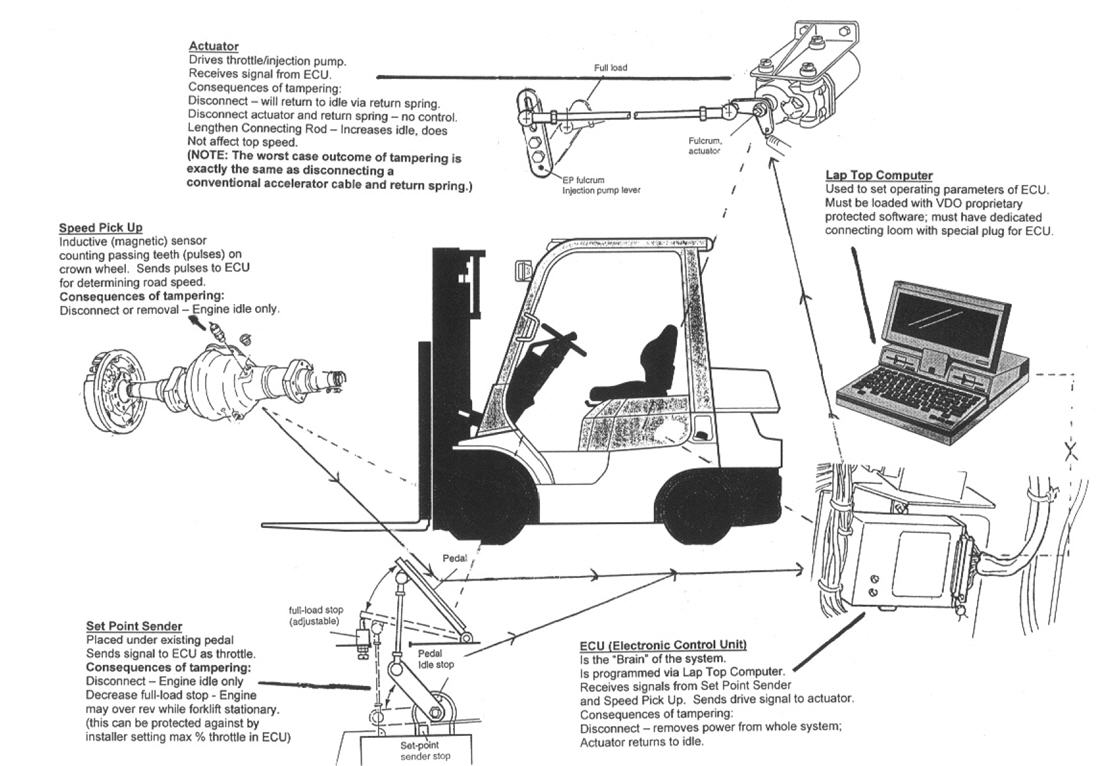

- Electronic Control Unit (ECU) – interprets required throttle position

- Actuator – interfaces to the vehicle and regulates engine speed

- Set Point Sensor – senses drivers desired throttle opening

SPEED SETTINGS

Due to its diverse operating conditions the E-Gas compact can have pre-set speed limit settings from 25-125 kph in its standard configuration and a second speed limit setting of 2-25 kph.

Engine RPM settings can be limited from 1000-8000 max engine RPM.

In order to make changes to any of the operating parameters of the E-Gas you require a diagnostic interface and associated software.